METHOD STATMENT FOR PIPE LEAKAGE TESING

METHOD STATMENT FOR PIPE LEAKAGE TESING

-

Purpose

The purpose of this method statement is to describe methodology for PIPEWORK LEAKAGE TESTING and to ensure that the requirements from technical specifications.

-

SAFETY PROCEDURE

The contents of this method statement shall form the basis of a toolbox talk for all operatives and ensure that the availability of (PPE) and tools provisions for testing prior the commencement of such works.

-

Protection and Safety Equipment

- Safety Helmet, Safety Shoes, Safety Vests

- Safety Belts, Safety Goggles

- Hand Gloves

- Caution Tape, Traffic Control Cones

-

Risk Assessment

- Flooding during

- Burst of pipe or fitting because of over

- Danger of falls from

- Falls, knocks or trips due to poorly lit areas within the

- Electrocution when using electric hand tools, extension cords

- Damage of paint and equipment due to over pressure test and theft of installed valves.

-

PROCEDURE FOR PIPEWORK LEAKAGE TEST

METHOD STATMENT FOR PIPE LEAKAGE TESTING 5.1 Pre-Commissioning Check

- Prior to start the test, refer to the approved installation and ensure that required materials are available at

- Supervisor to carry out a visual inspection of the work areas, materials, tools, safety equipment and confirm ready to commence works.

- Preparation of tools and materials such as pipe leakage test kit, accessories and hand tools prior to commence the works.

- Ensure all work areas are released by the main contractor before proceeding with the

- Check the location of pipe routing in relation to the structure and architect as indicated on the

- Fit blanking devices in accordance with the drawings and ensure that enable a blank to be cut-out after the testing is

- Access to adjacent to each blank is required.

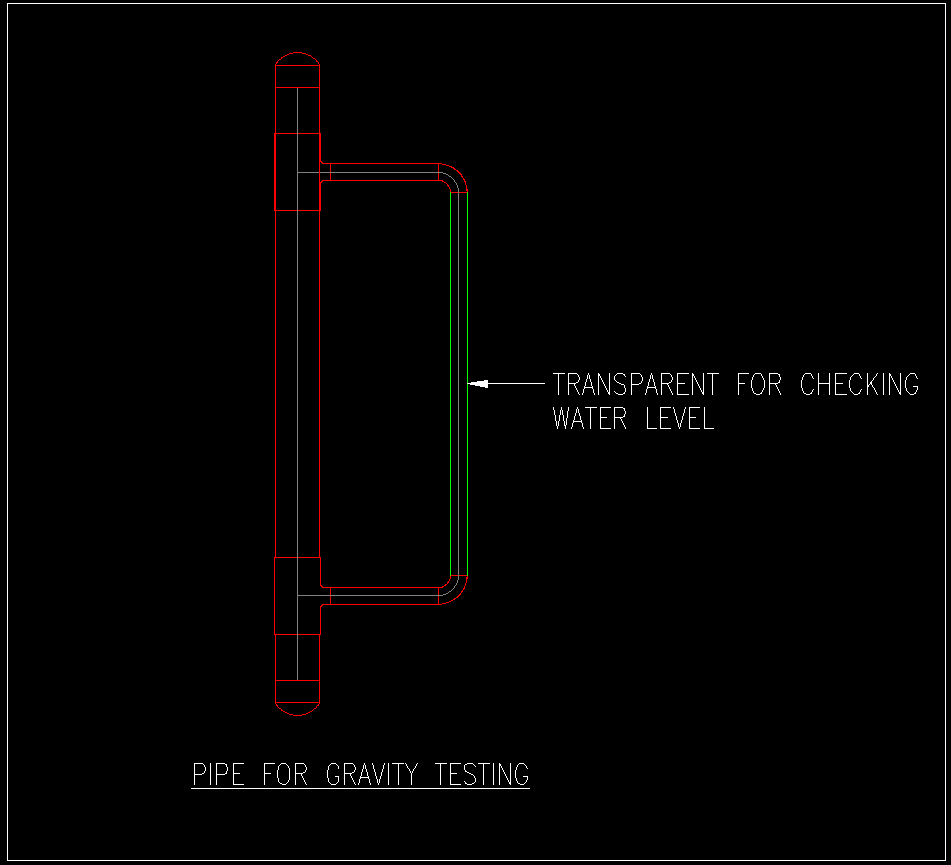

5.2 Gravity Test Methodology

- Remove all obstructions, debris and superfluous matter from the

- Sucre all drain stoppers and/or bags in the end of the pipelines and all associated branches under

- Ensure all pipelines with minimum 5 meters head and maximum 3 meters head from highest horizontal.

- Fill water to the pipelines at least 30 minutes before the test to allow for water

- Internal test shall be a minimum of 30 minutes and otherwise testing at least 8 hours.

- Measure the loss of water inside the pipeline.

GRAVITY PIPE TESTING

Subscribe

Login

0 Comments

Oldest